©Bosch.IO

©Bosch.IO

Welcome back to our journey through Bosch IoT Suite!

Over the past few months, you’ve had the chance to accompany Erika on her travels and follow her user journey as a new customer. For our last episode, we want to show both you and Erika things from another perspective – and hear what some of our current customers have to say about Bosch IoT Suite!

©Bosch.IO

©Bosch.IO

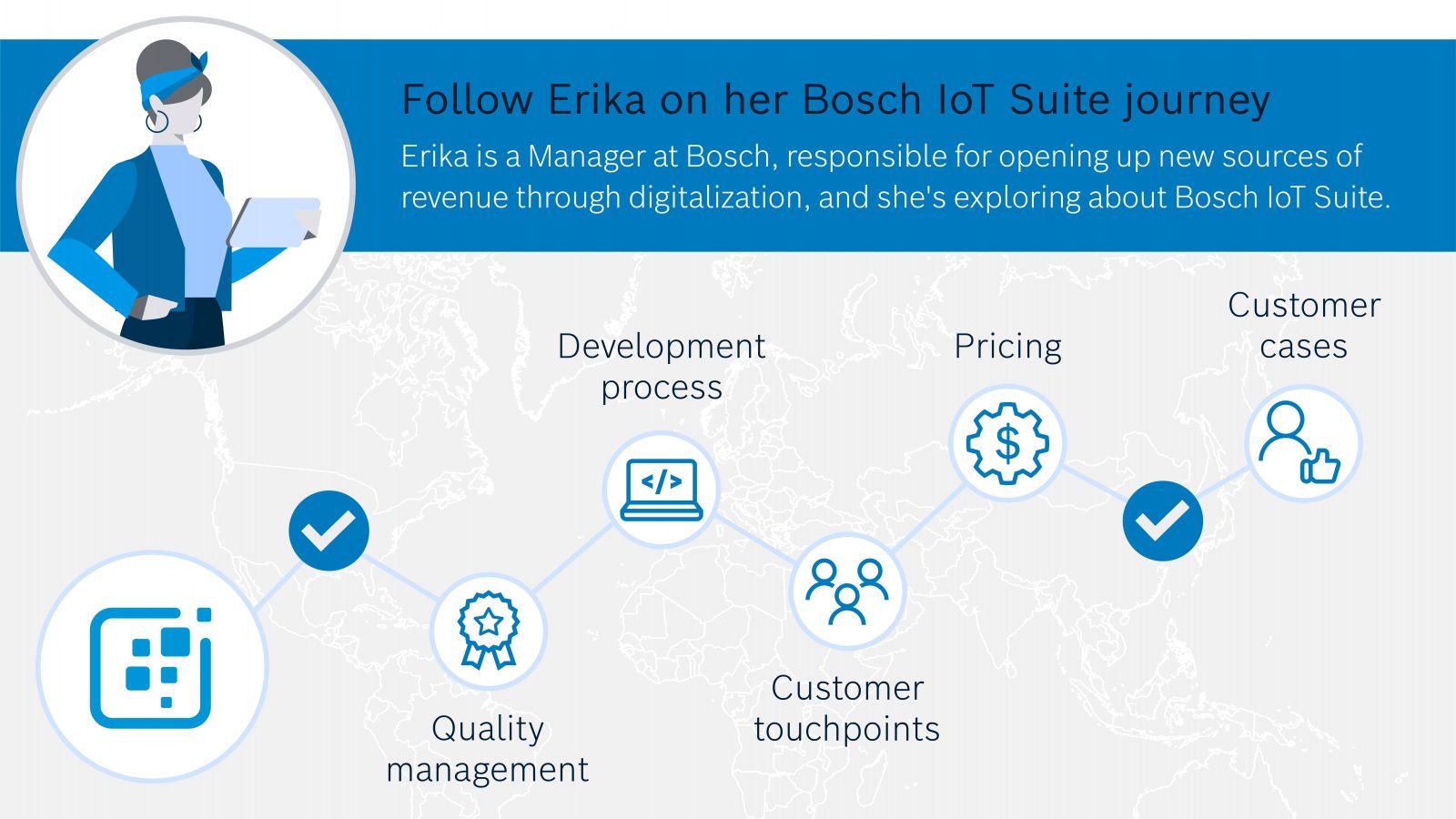

Erika's Bosch IoT Suite journey from quality management to customer cases.

We already have quite a journey behind us, so how about we take a quick coffee break and meet some Bosch IoT Suite customers? At my office’s coffee station right around the corner, we’ll meet with our first guest: Christian Grabe, the Business Owner of Telematics for off-highway machines at Bosch Rexroth.

Together with his team, he develops telematics and fleet management solutions for the off-highway market, like construction, agricultural and municipal vehicles. Hi, Christian – meet Erika!

Keep machines healthy: Data management in telematics

©Bosch.IO

©Bosch.IO

Christian Grabe

Christian Grabe is Business Owner at Bosch Rexroth's telematics unit for off-highway machines christian.grabe@boschrexroth.de

Here are your coffees! So, Christian, you’ve been a customer of Bosch.IO for quite some time now. How did you find your way to Bosch IoT Suite? “Back when we started, we were looking for ways to offer our customers fleet management, condition monitoring and advanced over-the-air services. Above all, a reliable data management solution was needed to handle the large amounts of data produced by the machines. With Bosch IoT Suite, we found what we were looking for: a mature solution from inside the Bosch Group that provided a lof of synergies and could be deployed quickly and easily.”

Today, Bosch IoT Suite is part of Rexroth’s BODAS Connect, a telematics solution that offers customers the connectivity hardware and IT infrastructure they need to check where their machines are at any time, whether there are any errors, and under which circumstances errors occur more frequently. Christian, why is this so important for off-highway machinery? “These machines are often used in remote areas, which makes maintenance much more difficult and costly. Reliable fleet management and condition monitoring are crucial in order to investigate malfunctions and alert machine operators to potential problems early on.” The basis for providing such services: tremendous amounts of data on the location and performance of all machines. Bosch IoT Insights provides the framework for storing, processing, and visualizing these large amounts of collected data. It includes scalable cloud storage and databases with state-of-the-art security as well as flexible, customizable visualization options, for example in the form of dashboards.

Meanwhile, Christian and my Bosch.IO colleagues have been working on new features to offer customers additional standard options. How has that been working for you, Christian? “Really well: both our teams are using agile methods, so there is a close fit in our ways of working. Being able to collaborate so closely and in joint development processes has been a great benefit of going with a Bosch solution.” So far, they have successfully implemented features like digital rights and role management, and custom processing pipelines, which offer customers the chance to incorporate their own algorithms and calculations in the data processing. “Our goal is to give our customers a way to manage their fleets quickly and easily – but also the chance to go more in-depth and add their own solutions if needed,” Christian explains. “Thanks to Bosch IoT Insights, our customers have many more opportunities for customization and multidimensional data usage.”

Thanks so much for your insights, Christian! Erika, what do you say: are you ready to meet another customer? “You bet!” Then come along: we’ll pay our customers from Bosch Thermotechnik a visit! They have production sites all over the world, and today, we’ll check in with the team in Lollar.

Hundreds of thousands of gateways, three different device generations – and one updating platform

Ulrich Schmitt

Ulrich Schmitt is Excellence Owner for IoT in the residential division of Bosch Thermotechnik ulrich.schmitt@de.bosch.com

Erika, this is Ulrich Schmitt, the Excellence Owner for IoT in the residential division of Bosch Thermotechnik. Along with his team, he is responsible for ensuring the connectivity of HVAC (heating, ventilation, air conditioning) devices in one-family and two-family houses: they enable heating contractors with installation, remote diagnoses and maintenance, and provide end users with smartphone apps that allow them to regulate the temperature of their HVAC device. Hi, Ulrich!

What made you decide to work with Bosch IoT Rollouts, Ulrich? “When we started our work many years ago, we were only connecting a few devices. Back then, it was easy enough for us to develop the infrastructure for software updates ourselves. But as time went on and more and more devices had to be updated, we realized how difficult it was for us to keep up.” Since HVAC devices usually have long service lives, Bosch Thermotechnik has to offer equally long support and updates for the gateways that connect these devices to the cloud. For Ulrich and his team, that used to mean updating new generations of devices as well as legacy devices that weren’t on the market anymore – a grand total of hundreds of thousands of devices from three different generations. In the end, going with Bosch IoT Rollouts made their job infinitely easier: “We are no longer responsible for maintaining the necessary IT infrastructure to update hundreds of thousands of devices. Instead, we can rely on the service offered by Bosch.IO around the clock. Going with a Bosch solution gave us the reliable, long-term support needed in our industry.”

Since Ulrich and his team had previously developed their own update infrastructure using varying network protocols, the Bosch.IO colleagues’ first task was to code adapters that allowed legacy devices to connect to Bosch IoT Suite. Then, starting with newer generations, the gateways were gradually converted to Bosch IoT Rollouts. “We’re currently wrapping up the legacy devices,” Ulrich explains, “and have managed the entire conversion without any disruptions for our customers.” In the meantime, Ulrich and Bosch.IO have been jointly developing new features for Bosch IoT Rollouts, like artifact encryption to ensure even higher IT security, and target types to make sure that devices receive only those updates that are meant for them. Looking back, how satisfied are you with your choice to go with Bosch IoT Suite, Ulrich? “For us, working with Bosch.IO has always been constructive and collaborative: we have tackled every challenge together. The pay-per-use pricing also allows us to differentiate between the costs of different device families – that was never possible before.”

Want to continue your Bosch IoT Suite journey? Contact us!

©Bosch.IO

©Bosch.IO

Sadly, that concludes Erika’s journey through Bosch IoT Suite: Over the past few months, we’ve met the team behind Bosch IoT Suite, learned about quality management, development processes, customer touchpoints and pricing at Bosch.IO, and met with real customers. But just because Erika’s journey is over doesn’t mean that yours has to be! If you’d like to learn more about Bosch IoT Suite, just get in touch with us – we’ll be happy to talk to you about your projects and how we can help you: Contact us

So long for now!