1. At which organizational level or with which function should our data analytics project start?

There is no best level or function. Where to start a project depends on several factors:

Is the concept of data analytics already well understood at your company?

If not, the best way to start is to hold a data analytics orientation workshop for both experts and management. The goal of this workshop is to impart a basic understanding of the possibilities of analytics and to identify potential use cases.

Does management have a (deep) understanding of the technical process?

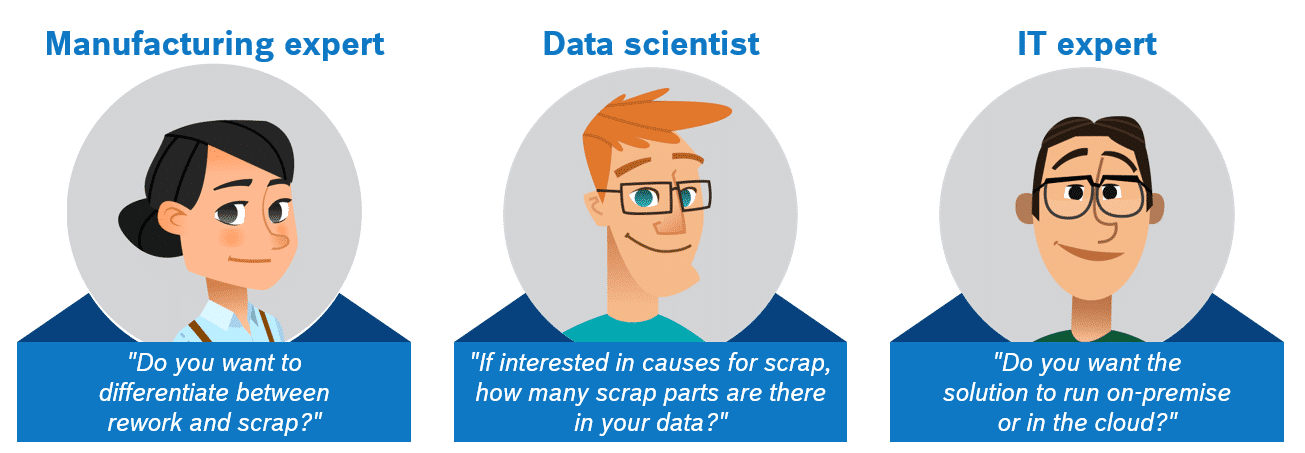

If not, a requirements workshop with production site experts may be your first choice. The output is usually a cause and effect diagram (see below). Typically, our data analytics team (comprising a mix of IT, manufacturing, and data science experts) asks in-depth questions, such as: “Do you want to differentiate between rework and scrap?” In the best case, it can be very helpful to involve management to achieve serious buy-in.

©Bosch.IO

©Bosch.IO

Has the problem that data analytics is expected to solve been defined concretely?

If so, you may opt first for an analytics tool. The problem can be as concrete as “EoL testing effort is too high and needs to be reduced.” An analytics team can then immediately start working with the production site experts to determine whether an existing test-time reduction tool can be applied or how it may need to be customized or expanded.

2. What perspectives do we need to manage in a data analytics project?

Thanks to a UX study conducted by Bosch, we know that there are three types of plant experts that need to be addressed, each one in a completely different way – e.g. more on a business level, more on a technical level, or more on a data level.

©Bosch.IO

©Bosch.IO

The skeptical type needs evidence of the benefits data analytics will deliver. To convince the skeptic, we need an excellent understanding of the ROI mechanisms, and we must be able to validate these mechanisms quickly with results, focusing on output, quality, and costs.

The open-minded type is interested in new ways to optimize things. Emphasis should be placed on explaining which methods are used, why certain algorithms are selected, and why the resulting prediction model is ready for application to live data.

The believer has usually already had exposure to data analytics and believes it can make a difference for the business. The best way to start is to immediately apply CRISP-DM (cross-industry standard process for data mining, see diagram below) with him or her and the team for the data analytics project.

©Bosch.IO

©Bosch.IO

In our experience, orientation workshops have generally proven to be very useful in obtaining the buy-in of all stakeholders. We usually start with the business question and then iterate by understanding the technical process and constraints relating to that question. More than once, our engineers have managed to convince customers that complex regression analysis can easily be communicated as a benefit.

Stefanie Peitzker

I have a graduate degree in management with a specialization in geography (University Augsburg, Germany). Since 2003, I work for Bosch.IO (formerly Bosch Software Innovations): I have built up marketing for Visual Rules, our Business Rules Management System and contributed in winning customers around the globe. Since January 2009, I run the Marketing Solutions team at Bosch.IO, an agile team of currently seven associates, all trying to permanently learn more about the customers´needs and market trends – focused on making software solutions a real experience.

Your data analytics team needs to acquire a basic understanding in three areas:

Business: As the customer, you need to tell them about the project objectives and requirements from a business perspective so they can convert this knowledge into a definition of the data analytics problem.

Data: Data preparation, modeling, evaluation, and deployment – everything from simple report generation to live deployment of predictive models. Pure data understanding has proven to be a solid foundation that is helpful in many industries, but there is no focus on manufacturing.

Technical process: You as the customer need to provide a basic explanation of the overall production value chain, e.g. the welding process, the laser process, testing, or the tightening process, depending on the question that analytics is to answer. This is where the analytics team needs the manufacturing analytics engineer.

4. What groundwork does my manufacturing organization need to do before deploying Manufacturing Analytics?

At first glance, data collection and preparation seems to be a challenge for many production experts. The groundwork for them is to make data available as needed. “We don’t have the data” isn’t a valid response. But it’s not rocket science. We recommend a data quality guideline that guides customers through the process of preparing data in terms of the quantity, quality, and validity needed for analytics.

©Bosch.IO

©Bosch.IO

5. What is the minimum amount of data required to apply analytics?

As a rule of thumb, we suggest that you have at least 15 observations or data sets per influencing variable. In other words, to analyze the influence of 30 process parameters on a quality indicator, at least 30 * 15 = 450 data sets would be required.

Generally speaking, of course, the more data sets you have, the better. Don’t worry – more data sets don’t significantly increase the amount of manual work. In addition, they have only a minor impact on the computing time, which is usually negligible with the right data analytics IT infrastructure.

Since the quantity, quality, and validity of the data acquired and prepared are crucial to project success, it pays to invest in this phase of your project. To further guide you through it, we have pooled our experience from many projects in a set of data quality guidelines. Our customers use these guidelines to generate an adequate data base without investing unnecessary time or money in data collection.

6. Can I still leverage analytics if my company doesn’t have any data scientists or a big IT team?

This is exactly what your professional analytics partner will contribute to help you realize your project and solution. A capable team is made up of a mix of manufacturing engineers, IT experts, and data scientists. This combination is the key to solving your problem with a lean analytics approach, since developing your analytics-based solution requires an understanding of business, data, and the technical process. You don’t need to hire any data scientists for your organization. Your professional partner will present pre-project workshops on basic analytics, where you will learn how to identify possible use cases and help validate the developed models. You will then apply this knowledge in project meetings to discuss the results.

©Bosch.IO

©Bosch.IO