DIRK SLAMA Sébastien, you are working on the Airbus Factory of the Future project. This sounds like a very ambitious venture. What areas does the project cover?

SÉBASTIEN BORIA There are currently more than 8,000 Airbus aircraft in operation, with 15,276 orders for aircraft logged as of January 31, 2015. Each aircraft is a complex product consisting of millions of parts that have to be assembled to perfection. Integrating innovative production techniques is vital for our productivity. Today, digital mock-ups, laser projections onto aircraft bodies, and complex 3D environments have already been fully integrated into our processes. Because each generation of our manufacturing lines has a lifetime of more than a decade, the Future Factory has to adopt an outlook that goes well beyond just one year. There are a variety of important considerations here, including robotic exoskeletons for assembly, advanced robots (from standard to cobotics), ALM technology, the virtual plateau and digitization of the shop floor, integrated production, and so on. The aim is to leverage emerging lab technologies that can be adapted or matured in order to improve our manufacturing processes.

But the focus of your own work is a bit more specific, isn’t it?

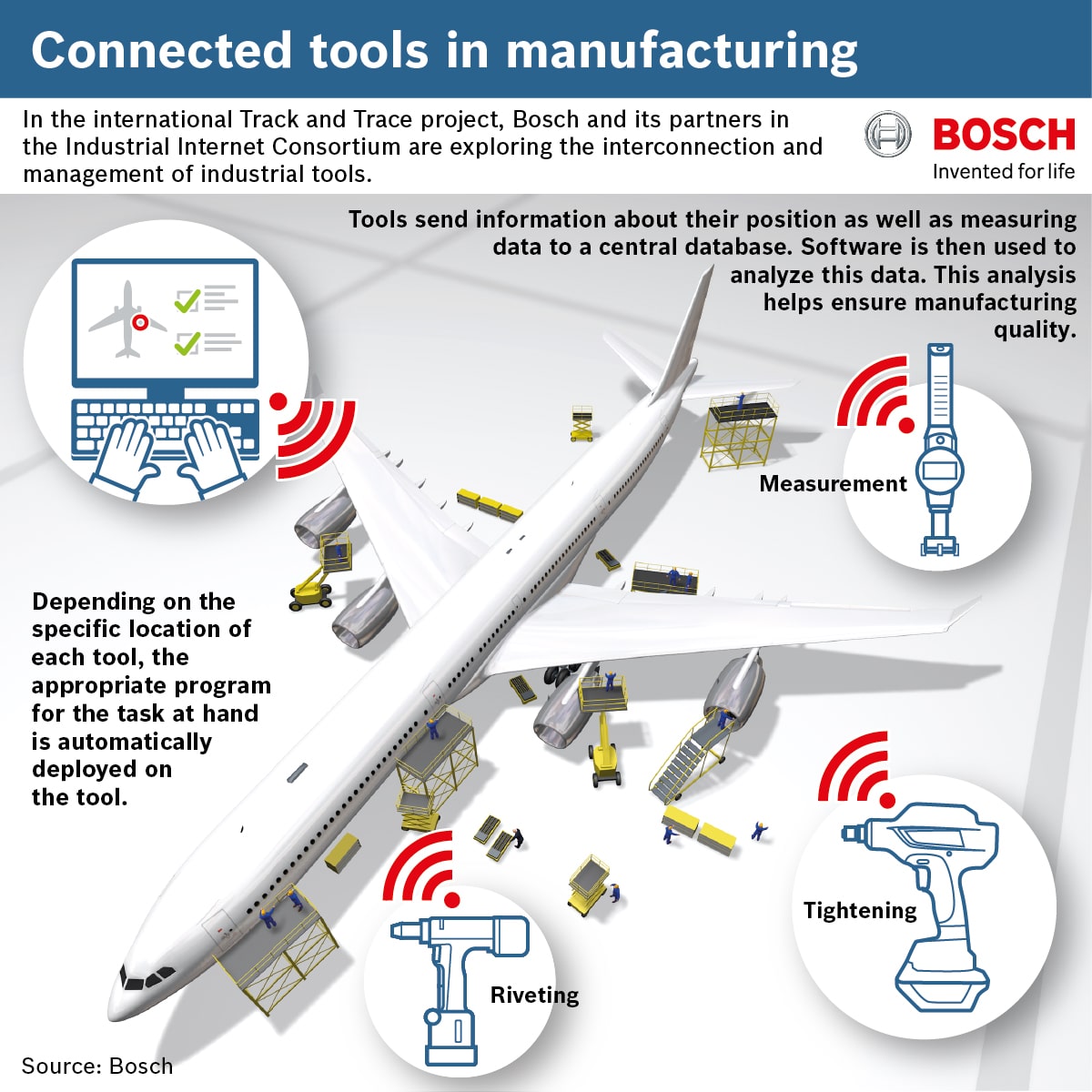

Yes, I mainly focus on smart production and advanced robotics. We are in the process of implementing a “smart workshop” that uses intelligent, connected production tools to streamline processes and provide error-proof processes for shop floors.

Can you give a concrete example?

Sure. Think of the hundreds of thousands of point-based process steps that need to be completed in order to assemble an aircraft. Because of the sheer volume of process steps involved, it’s not possible to have an individual task for each step at workcell level. Instead, these process steps need to be managed collectively as process sequences. Most assembly tasks involve a drilling process, a point-checking (i.e., measurement) process, and a tightening process. These processes can involve multiple stages within one takt, be spread over several workcells or assembly lines, or even shared by various production operators. For example, different torque and angle parameters are used in different phases of the same tightening process, at a single 3D location, for example. Therefore, if something goes wrong with one of these processes, it could lead to costly, dedicated fixes, just because the part is not in the correct workcell on the shop floor. So there is enormous potential for improving these processes by making the relevant handheld tools more intelligent and connected, by dynamically configuring the tools for the specific task at hand, for example.

©Bosch.IO

©Bosch.IO

Overview of the Track & Trace testbed from the Industrial Internet Consortium.

What types of tool are you looking at specifically?

Currently, we are focusing on smarter handheld drilling, tightening, and measurement processes, either through standard tools with embedded intelligence or through wearable computer intelligence embedded in operator suits, such as belt systems, for example. Later, we will also look at integration with robots and CNC machines using the same architectural design.

And what does your solution look like?

Everything is linked to a platform which combines specialized hardware and software. In other words, we are using an architecture that is linked to distributed intelligence that is embedded in every system involved in our processes. First of all, there is the tool intelligence itself. Handheld power tools used in our Future Factory environment will have to either have an onboard control unit or at least be able to support wearable controllers. This is important for ensuring local processing of process input data, in combination with onboard sensors and actuators linked to the physical tool process. And leveraging wireless connectivity for the most part too, of course.

And what about tool integration?

In the past, we took a more traditional, centralized approach, but this is not efficient enough to manage heterogeneous systems in real time, given the imperative for lower infrastructure costs. This is why we are now looking more closely at solutions that work as a mashup of interconnected tools. We need to transfer data from one system to another or perform the relevant synchronization, but only when requested by the local intelligence, or when it serves a purpose for the overall process. In other words, not every tool is connected to a central backend all the time. But tools can connect with each other to exchange information and instructions. This solves many problems – for example, if you are working inside an aircraft where there is no wireless network available.

How do you track tools and map tool information to production data?

Indoor localization is important, and so is integration with data from MES and PLM systems. Automatically reconciling localization data for tools and work items with PLM data is also important. Reconciliation is requested based on various trueness values (see ISO 15725) and depending on the application. Tracking a tool on the shop floor or within a workcell is not the same task as tracking a handheld tool tip from one position to another when carrying out processes on an individual part. In the first case, inaccuracy in tracking data can correspond to tens of centimeters or even meters, while in the second case, inaccuracy can be a matter of tenths of millimeters. Again, system integration has to take into account context-based adaptive behaviors in order to avoid errors and nonquality outcomes.

So you’re integrating localization data with 3D PLM data?

Well, not exactly. We have learned from experience that CAD/CAM data models coming directly from engineering can sometimes be too detailed and fine-grained for our purposes. So we are currently developing an intermediate layer that works with a simplified XML dataset for geo data. This layer helps to integrate the power tools with the 3D PLM layer. Also, you can’t expect shop-floor workers to use a full 3D modeling environment to configure their working environment. This means that we need to build a simpler configuration application.

Enterprise IoT

This text was excerpted from the book Enterprise IoT by Dirk Slama, Frank Puhlmann, Jim Morrish, and Rishi M Bhatnagar (O’Reilly, 2015). For insights on the Industrial Power Tools Vendor Perspective read the interview with Martin Doelfs from Rexroth in Enterprise IoT.

Book: Enterprise IoTIt sounds like a lot of different types of production equipment and IT systems have to interact and work together. How do you roll this out in a very heterogeneous environment with a large number of different suppliers?

Dissemination is important, as is a clear focus on open interfaces and interface-based integration. Software openness through an API is the main enabler of efficient integration. We are therefore defining neutral interfaces based on robust standards, which will enable our own engineers as well as suppliers and partners to develop tools and applications that fit into our overall shop-floor support system. Because of the high level of heterogeneity we have here, this type of integrative approach is central to our future production system.